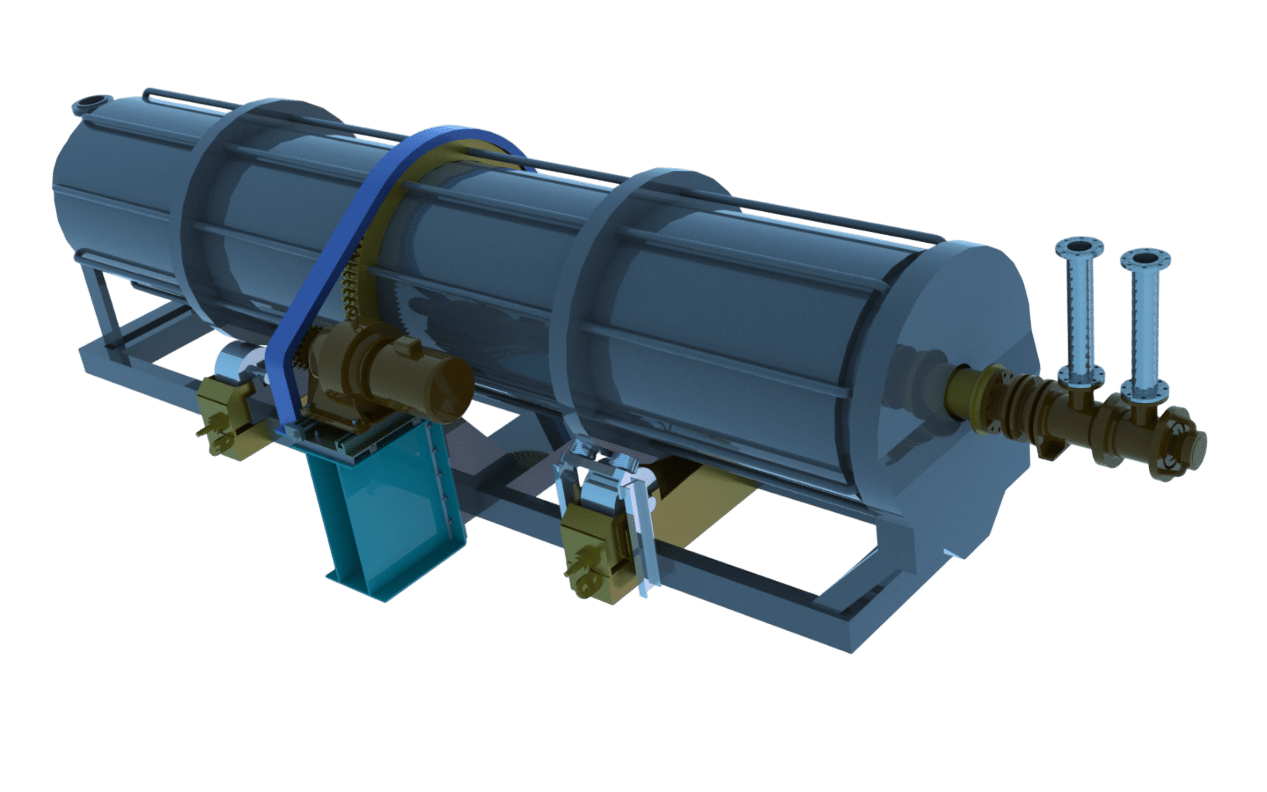

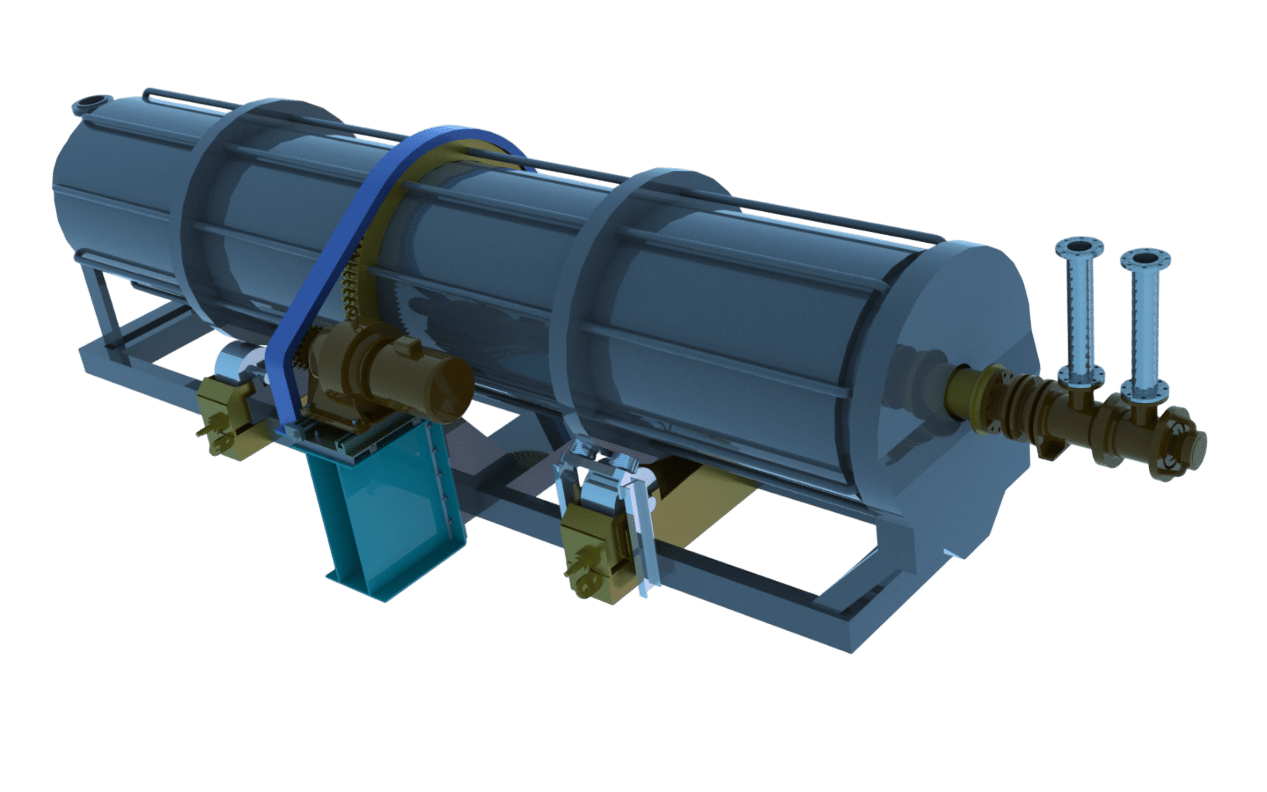

Rotary Ash Cooler

Rotary ash cooler is usually used for cooling the hot bottom ash discharged from CFB boiler furnace in coal fired power plants, biomass power plants, cement works, etc.

Rotary ash cooler is usually used for cooling the hot bottom ash discharged from CFB boiler furnace in coal fired power plants, biomass power plants, cement works, etc.

Solids enter the rotating barrel from one side and are cooled by spiral and longitudinal fins inside the barrel. The spiral fins lit and convey the solids continuously to the barrel exit. There is no mechanical pushing force on the solids therefore there is little erosion on the fins and barrel. The solid flow increases with the barrel rotating speed and decreases to zero when the barrel stops rotating. Ash cooling capacity is automatically adjusted by barrel rotating speed. The rotating speed is controlled by a variable frequency motor which is DCS-controlled depending on bed pressure.