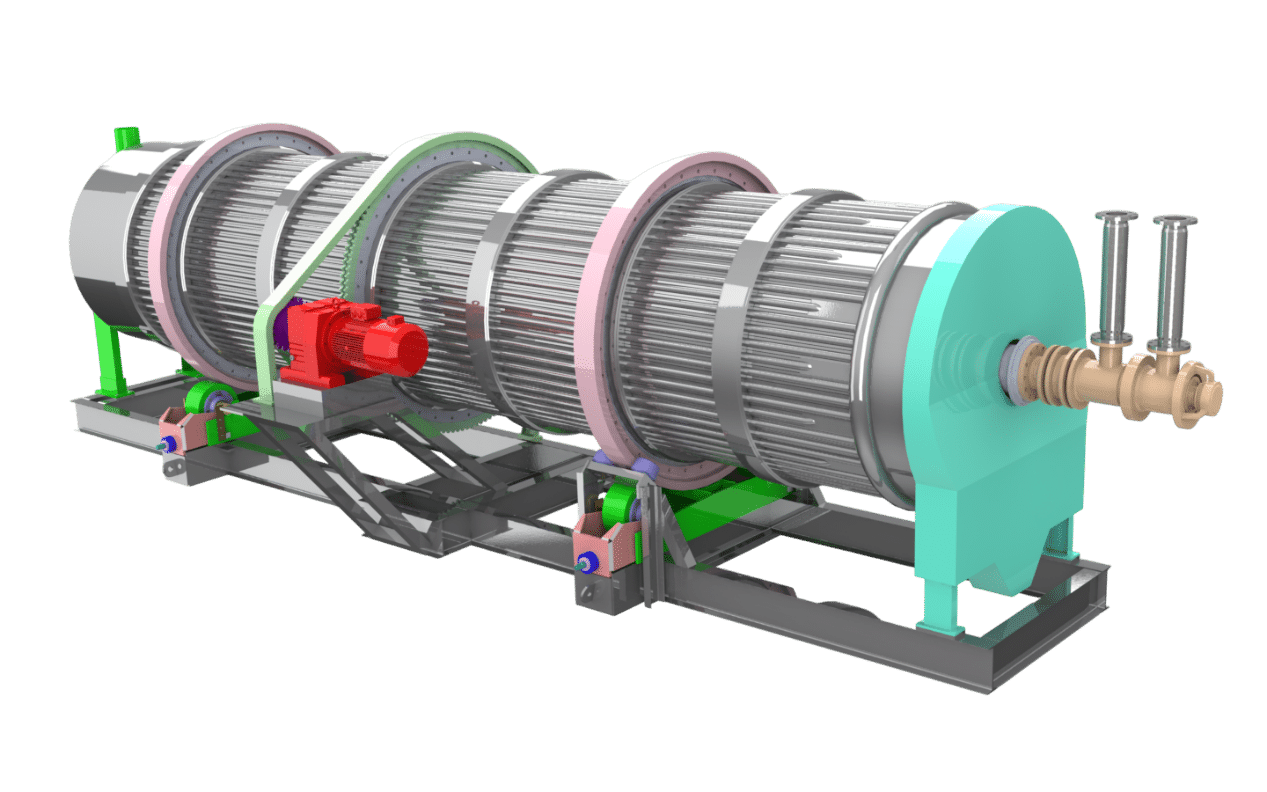

Rotary Drum Cooler

Rotary drum cooler is a new type cooler used for cooling bulk materials and has been applied in cooling of Calcined coke, Semicoke, Needle coke, Magnesium reduction, Steel slags, Manganese reduction, Graphite anode materials, etc.

Rotary drum cooler is a new type cooler used for cooling bulk materials and has been applied in cooling of Calcined coke, Semicoke, Needle coke, Magnesium reduction, Steel slags, Manganese reduction, Graphite anode materials, etc.

It consists of rotating drum, material inlet section, material outlet section, cooling water system, drive mechanism, etc. The drum consists of an outside cylinder with membrane pipes and an inside cylinder with tubes. There is designed with guide fins inside the drum for guiding the materials to cooler outlet and transfer the heat from the hot materials to cooling water. As hot materials enter the bottom of the drum through the inlet, ash starts to accumulate around the inlet till equilibrium is established between the material gravity and the resistance of the materials in the barrel. As the drum rotates, the material resistance is reduced inducing more bottom materials into the drum. The material flow is a linear function of the rotating speed. The faster the drum rotates, the higher the material flow is. In the process of material moving, heat exchange occurs between material and cooling water.